Factory source Organic Waste Composter - Compost turner manufacturer eco friendly compost turner sugarcane bagasse organic fertilizer compost machine – TAGRM

Factory source Organic Waste Composter - Compost turner manufacturer eco friendly compost turner sugarcane bagasse organic fertilizer compost machine – TAGRM Detail:

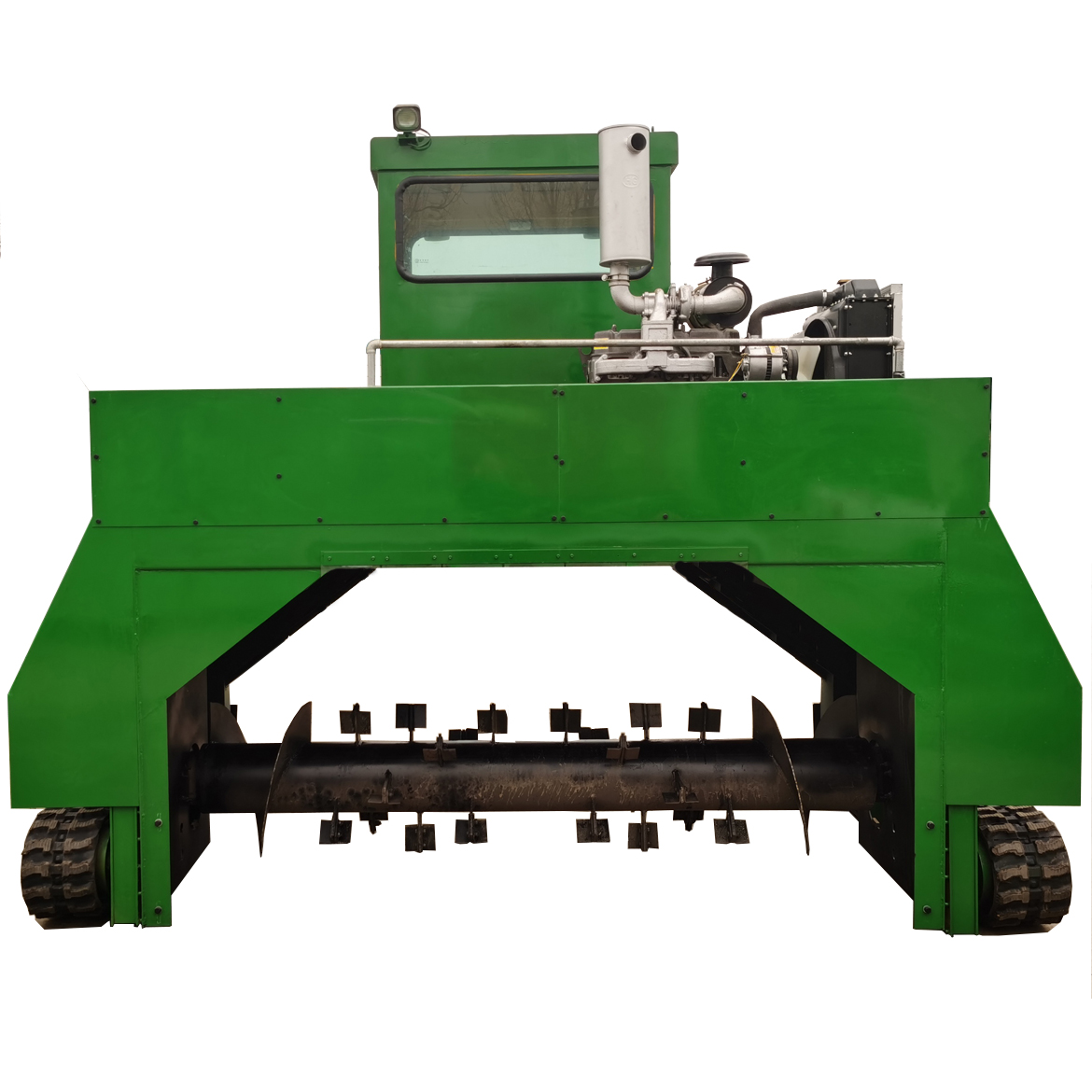

Product Pictures

Product parameter

| Model | M2600 | Ground clearance | 130mm | ||

| Rate Power | 68KW | Ground pressure | 0.46Kg/cm2 | ||

| Rate speed | 2200r/min | Working width | 2600mm | Max. | |

| Fuel consumption | <235g/KW-h | Working height | 1200mm | Max. | |

| Battery | 24V | 2x12V | Pile shape | Triangle | 45° |

| fuel capacity | 40L | Forward speed | L: 0-8m/min H: 0-24m/min | ||

| Track tread | 2830mm | W2 | Rear speed | L: 0-8m/min H:0-24m/min | |

| Feed port width | 2600mm | W3 | Turning radius | 1875mm | min |

| Oversize | 3400x2330x2850mm | WlxLlxHl | Drive mode | Hydraulic | |

| Weight | 2600kg | Without fuel | Working capacity | 720m3/h | Max. |

| Diameter of roller | 497mm | With knife |

How to make organic fertilizer by TAGRM’s compost turner?

1. Make sure the organic materials content reach to around 50%.

2. Make a compost pile that is suitable for the compost machine working size.

3. Use compost turning machine to turn, mix, crush and oxygenate the composting materials on a regular basis.

4. Check the fermentation situation. When the C/N<0.6, temperature of compost is stable and similar to temperature of environment, the smell of compost similar to clay, the color of compost close to black color, the compost structure is loose, the fermentation is done.

Product Video

M2600 compost machine testing film roller on factory. M2600 compost turning machine mixing vegetable.

Details Images

Packing and shipping

The main part of the compost machine will be packed in nude, the rest parts will be packed in box or plastic protect.

If you have any special requirements for packing, we will pack as your request.

Contact Us

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for Factory source Organic Waste Composter - Compost turner manufacturer eco friendly compost turner sugarcane bagasse organic fertilizer compost machine – TAGRM , The product will supply to all over the world, such as: Rotterdam, USA, Brazil, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.